Part C Project

"New Sub Assembly Line Design & Integration in an Automotive Environment.

In partnership with Bentley Motor Limited".

Problem:

-

Launch of the new Bentley Bentayga SUV into production, requiring all production areas to be optimally designed & set up before this happens.

-

The rational of this project has been to determine the most suitable location, method of delivery & system to provide the assembly of the Bentayga’s fenders & integrate them back into the main already established production line, in a restricted build hall.

Research:

-

To gauge theoretical background theory, the current methods & thought process in the design of automotive production lines & the uses of lean considerations in manufacturing were explored.

-

Additionally, looking at the trends in the automotive market & what future considerations would need to be made, including a review of computer based simulation methods that could be used to optimise & refine the production layout.

Bentley production & demand increasing

http://www.statista.com/statistics/386352/british-luxury-car-brand-bentley-global-production-volume/

Limitations:

-

Main line runs at 17.5 minute takt time, must not impact this time.

-

Line side space limitation for fixture of 2000x1800mm footprint & selected area build constraints.

-

Decision between; all-in-one build fixture & transportation dolly or use of existing static build fixture & simpler transportation dolly.

-

All designs must adhere to company visual & transposition standards as will be moved manually & via a Tow-motor.

Design:

-

Configuration of bespoke parts stillage rack for the 12 parts require in the build.

-

Varied concept development of fixture/transportation dolly & review against the 51 point specification, with additional company feedback.

-

Generation of precise CAD model of final design with production of 1:10th scale representative model.

-

Ergonomic assessment of design with selected operator characteristics.

-

Critical examination of concern areas (FMEA) for conformation of proposal & suggested design improvements.

-

Detailed costing & material choice review of all parts in design for later comparable costing evaluation.

-

Supplier quotation to show proposals budget adherment & implementation strategy.

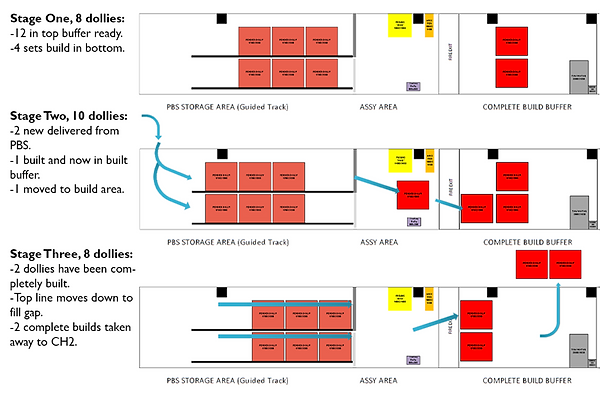

Area flow:

-

Review of 2 different area locations & their potential.

-

Analysis of different flow, layout patterns & operator movement.

-

Timing measurement analysis of the proposed system for optimisation.

Outputs:

-

Design of a bespoke, handed, carousel, all-in-one fixture that carries four fenders through the entirety of the system.

-

A fully functioning system that has the capability to move, build & deliver the fenders 22 stations later down the line

-

Throughput time (fixture set, PBS ST1-CH2 ST13): 286.00 minutes (takt+loading+transport)

-

System time (fixture set to return to original position/ whole rotation): 347.75 minutes

-

Scope to be reduced in takt time by 28.50% & integrated safety buffers at both ends of the sub-assembly.

-

Linear sub-assembly area that can hold & flow up to 24 sets of vehicle fenders & allow easy logistical delivery of parts & interaction with fixtures.

Future:

-

Details of all the findings will be handed over to the ‘Production Planning’ team and the BY63X production line manager for review, with the scope of integration if accepted.