Portfolio

"Below is a chronological display showcasing a sample of work thoughout my career so far. With most completed individually and others as a group, where I took a leading role providing direction for the group, deligating tasks and organising the projects."

Year 3 of University:

-

Individual project; design of a sub assembly area system & fixture for Bentley Motors Limited (more information can be found on next page).

-

Design of an automated laser drilling turbine manufacturing line.

-

Dimensional variation model analysis.

-

Re-design for optimal manufacture of a blender & pen using Boothroyd & Lucas methods.

-

Engineering management; law, finance & quality.

-

Finite element analysis of a bike frame.

-

Manufacture planning modelling, using varying capacity plans.

-

Concept design of a theoretical energy harnessing device for McLaren.

-

Sustainable analysis for manufacturing & assembly of a laminator.

Industrial Placement

A year working at Bentley Motors Limited in manufacturing, to gain my DIS (diploma in industrial studies), involving:

-

Launch support of the limited Continental GT3-R into production.

-

Quality checkpoint reconciliation of Continental & Flying Spur line.

-

Defect analysis & improvement.

-

Line balancing & work force optimisation.

-

Cost reduction & improvement of lean manufacturing.

Year 2 of University:

-

Ergonomic modelling & assessment, Mercedes Benz Actros Big-space 2500x2300

-

Sagentia design consultancy project, conceptual bike lock design.

-

Implementation of innovative use for graphene, water purification.

-

Catapult design & calculation of trajectory.

-

Plane design optimisation using Excel modelling.

-

BAe systems ship part manufacture & cost planning.

-

Conceptual container design using external influences and mechanisms.

-

Structural crane analysis using bespoke software.

-

PCB manufacturing analysis & solder paste printing.

-

Management report on JLR & their change in structure.

-

Software engineering with C-Sharp coding for a forge calculator & washing machine.

-

Statics fundamentals

-

Design of machine elements; lubrication, springs, gears, bearings & bolted joints.

Year 1 of University:

-

Beam design & analysis project; 180kg capacity on 0.368kg structure.

-

Hand render & display; high pressure pump.

-

Design & visualization CAD; bike shock.

-

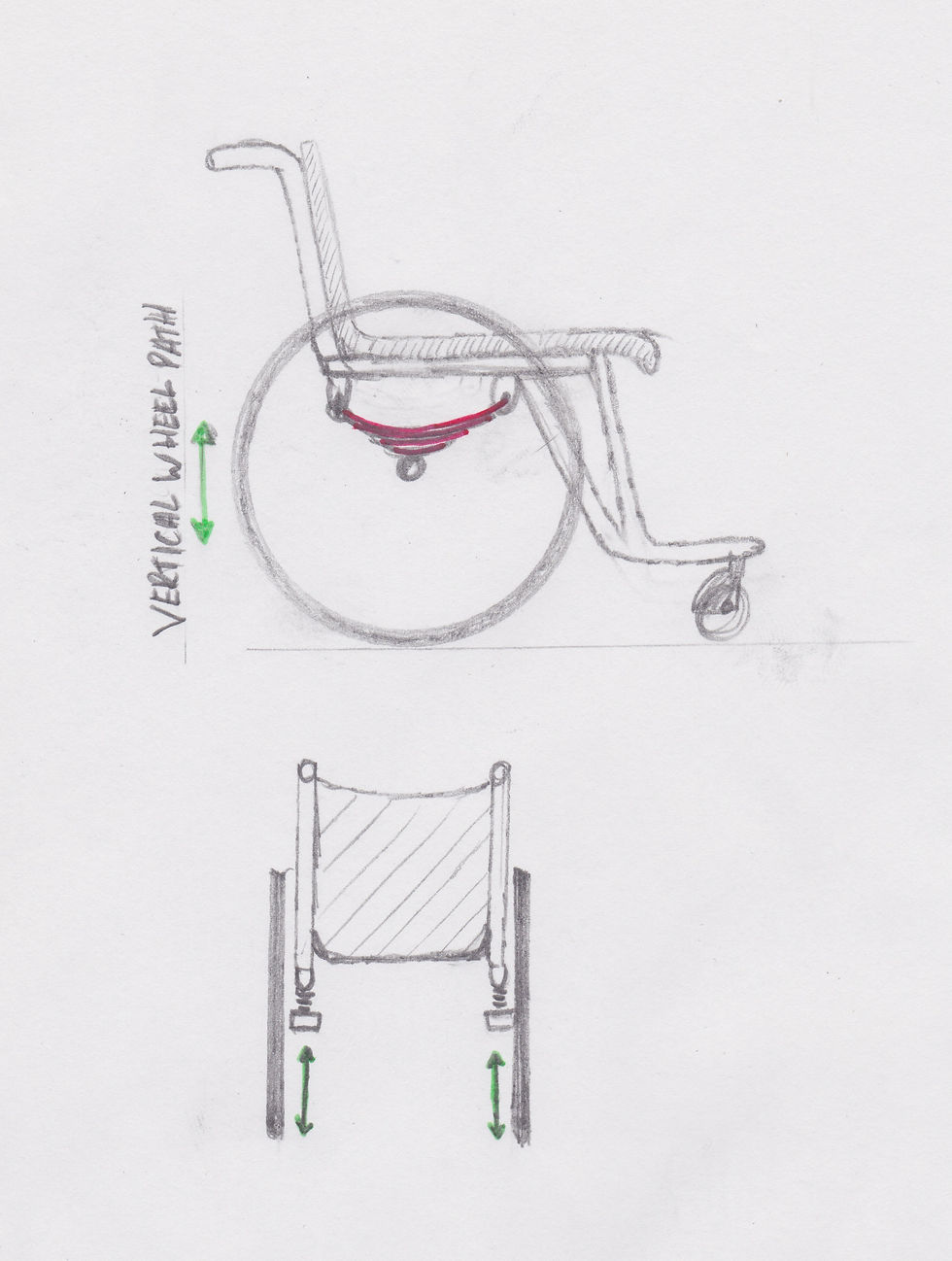

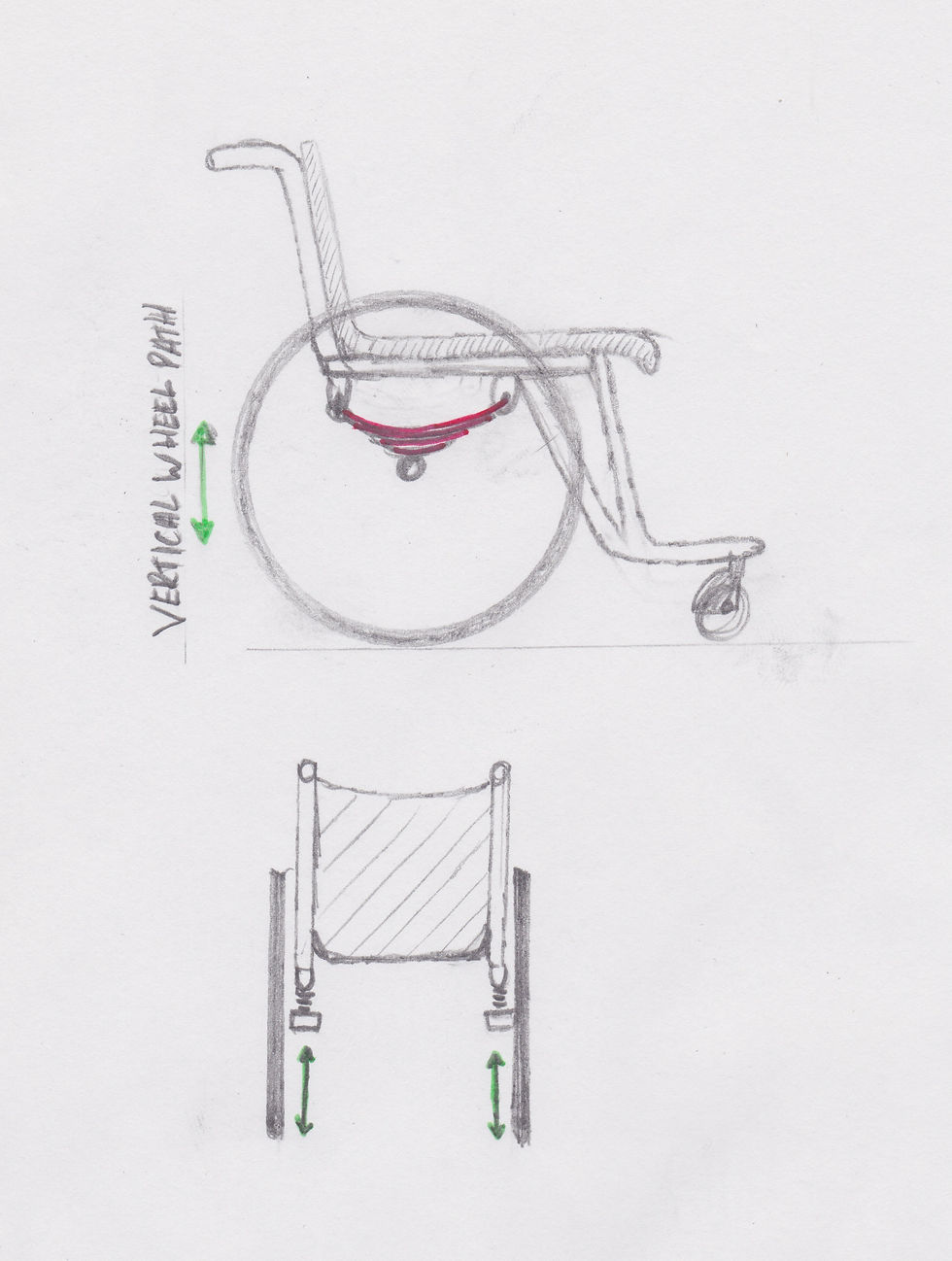

Healthcare accessory design, market & ergonomics of an interchangeable wheelchair cover.

-

Engine material & manufacture review; k-series rover.

-

Product dismantle & discover, hand blender for material choice & design.

-

Design & visualisation; vice.

-

Ergonomic assessment of desk design in SAMMIE.

-

Learning of design parameter for; milling, turning, CNC machining & welding.

-

Electronics theory.

-

Engineering science.

-

Materials & manufacturing.

-

Mathematics.

Design & Technology, Product Design Project:

For my A-Level project I designed and made a bike workstand, manufacturing every component in my design, whilst also incorporating a unique clamping device into the stand. The stand was foldable, height adjustable, could hold a bike up to 30kg and rotate it 360 degrees, whilst clamping multiple shapes and sizes of tubes. Including a in-depth writeup of the project, I gained and A* for all my work.

Design & Technology, Resistant Materials Project:

As my final project in GCSE D&T I designed and made a stylish oak side table. The key features of which, were to organize and store electronic devices whilst still being aesthetically pleasing for the set environment. I constructed it by hand all from solid white oak and finished it with soft closing ball bearing draw runners and an inlayed glass top.

Art

The display of work to the right show the portfolio produced over the two year of GCSE Artwork, including my exam pieces. I covered sculpture, clay work, building design, painting and drawing to obtain 100% mark.